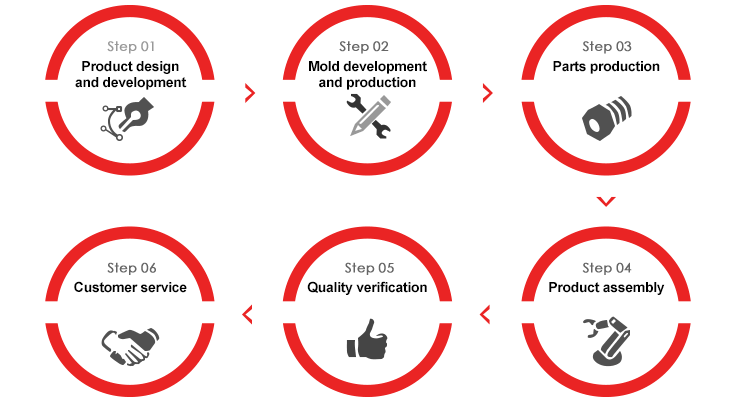

Full-process production, strict control of product quality

Dorabo's full-process production effectively controls product quality, shortens the production cycle, and has a (CNAS) certified measurement laboratory to do standard R&D design verification for customers to meet the electrical/mechanical performance requirements of the product. With good technical ability, high-precision product quality, high-efficiency production capacity, and flexible automation, we provide fast, convenient and comprehensive services.

|

R & D team The R&D center located in Shanghai, China is responsible for the research and development of Dorabo terminal blocks and the institutional design of related electronic products, and provides customized services to meet the special product needs of customers. Dorabo R&D Center has a complete R&D facility and R&D team, with R&D professionals in product design, process R&D, mold design, etc., and has been rated as [Shanghai Foreign R&D Institution] by [Shanghai Science and Technology Department]. Many high-tech products of our company have been patented every year. Based on a long-term perspective, in order to adapt to the ever-changing market, Dorabo meets the needs of the market through continuous innovation. |

|

Mold making With high-tech personnel in mold design and mold processing, Dorabo independently designs and manufactures high-precision and high-quality metal molds and plastic molds, and provides efficient mold making services. |

|

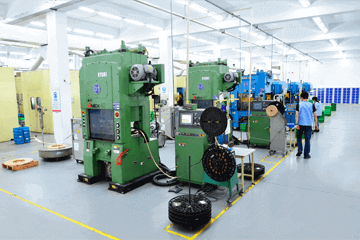

Press forming Good terminal block products start from stamping. Dorabo has various precision punches and metal processing machines from Switzerland, Japan and Taiwan, which provide a good guarantee for the production of various high-quality precision metal parts. |

|

Injection Molding Dorabo has vertical and horizontal injection machines, as well as technology of mold design, manufacturing, and injection molding to meet the complete production and service from design to manufacturing and the color requirements of various plastic bodies to ensure the stability of injection molding quality. |

|

Screw production Dorabo Screw Factory uses equipment such as molding, thread rolling, washer assembly and grooving with various auxiliary equipment and optical screening machines to provide customers with stable quality screws. The factory provides various terminal block screws and customized screws which meet the salt spray test requirements that are higher than the industry, and enhance the corrosion resistance and durability of the product. |

|

Electroplating and surface treatment We have formulated the production process and process, and established a complete and rigorous management system. Our equipment and process are echoed, which can meet the electroplating specifications of various products. The concept of harmonious coexistence of mankind and nature,and coordinated development of economy and environment have been deeply rooted in the hearts of the staff of the electroplating plant, and the Dorabo electroplating plant has continued to improve the production process. Dorabo is committed to improving the production environment and continuously improving its wastewater and waste gas treatment capacity. It has obtained the "Shanghai Pollutant Discharge Permit" issued by the Shanghai Environmental Protection Bureau, and has met the strict requirements of the [Special Environmental Monitoring Project for the Yangtze River Basin]. While creating benefits, we strive to achieve corporate social responsibility and create win-win conditions. |

|

Equipment and assembly technology The production mode of small quantity, variety and short delivery time is the general trend in the industrial application terminal block industry. In order to adapt to the changes in the market, Dorabo has three production modes in terms of assembly technology: automated assembly, semi-automated assembly and manual assembly. Different types of production modes are planned for different types of products.

Dorabo Automation R&D department can independently research and develop automated assembly machines. Before each equipment is assembled, strict quality control is set up, and the possible failure status is fully evaluated, which creates a responsible partner for you. Manpower assembly is the dynamic production model of Dorabo. Adhering to the idea of "being delightful for connection." Employees rely on mutual unity to produce high-quality and high-efficiency products. Dorabo continuously improves production efficiency and product quality on the road of industrial control,and pursues better and more comprehensive service quality to ensure customer satisfaction. |

|

Sales service Dorabo's management team upholds a high degree of service enthusiasm to make customers " being delightful for connection", and has more than 20,000 customers. Through the professional team of Dorabo, we understand the real needs of customers, provide professional technical consulting services, respond to customer needs quickly and immediately, and provide customers with satisfactory solutions. Dorabo participates in large-scale exhibitions in various places every year and frequently visits customers, aiming to get close to the market, understand customers, and establish long-term mutual trust and win-win cooperation with customers. |