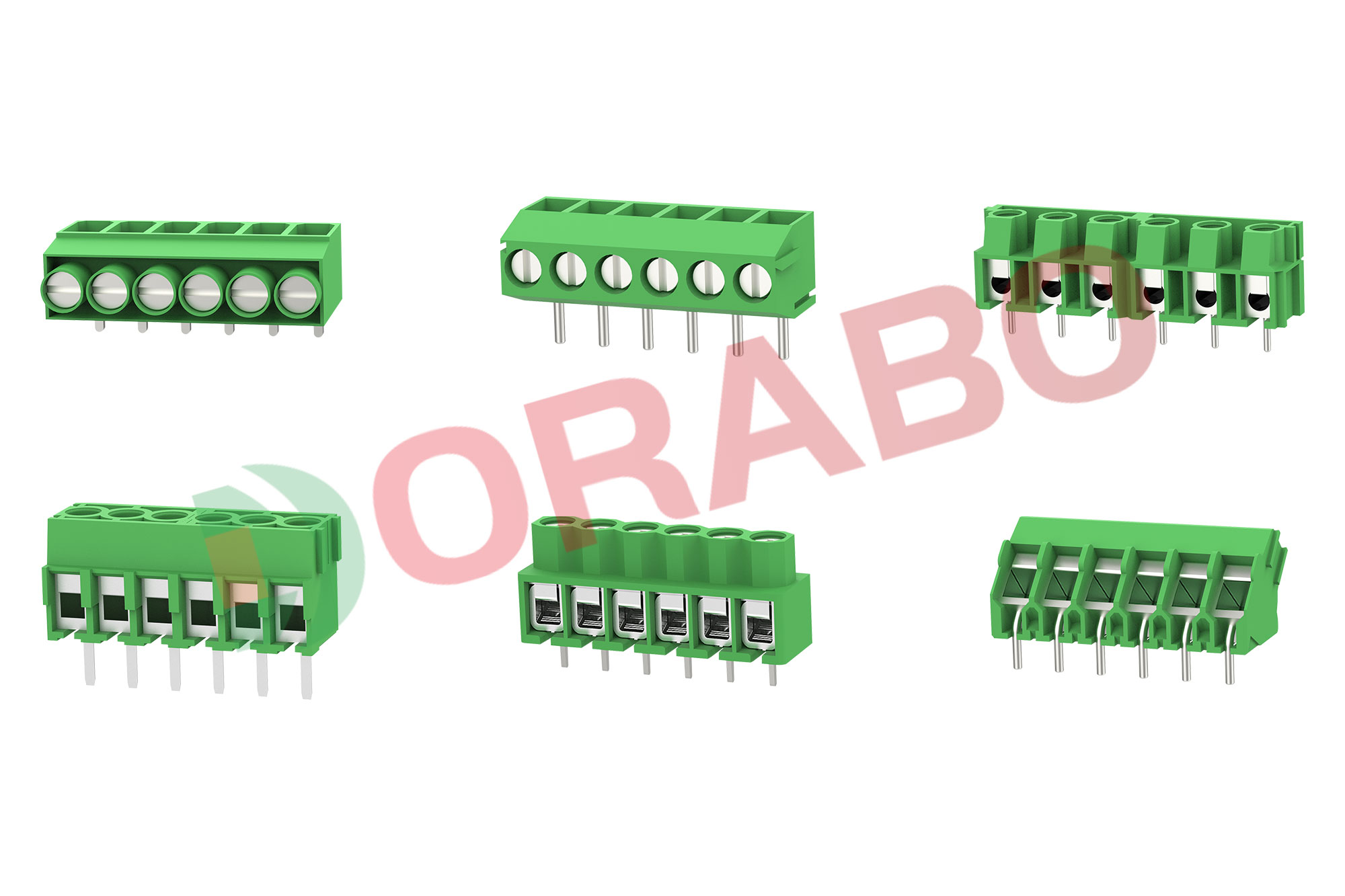

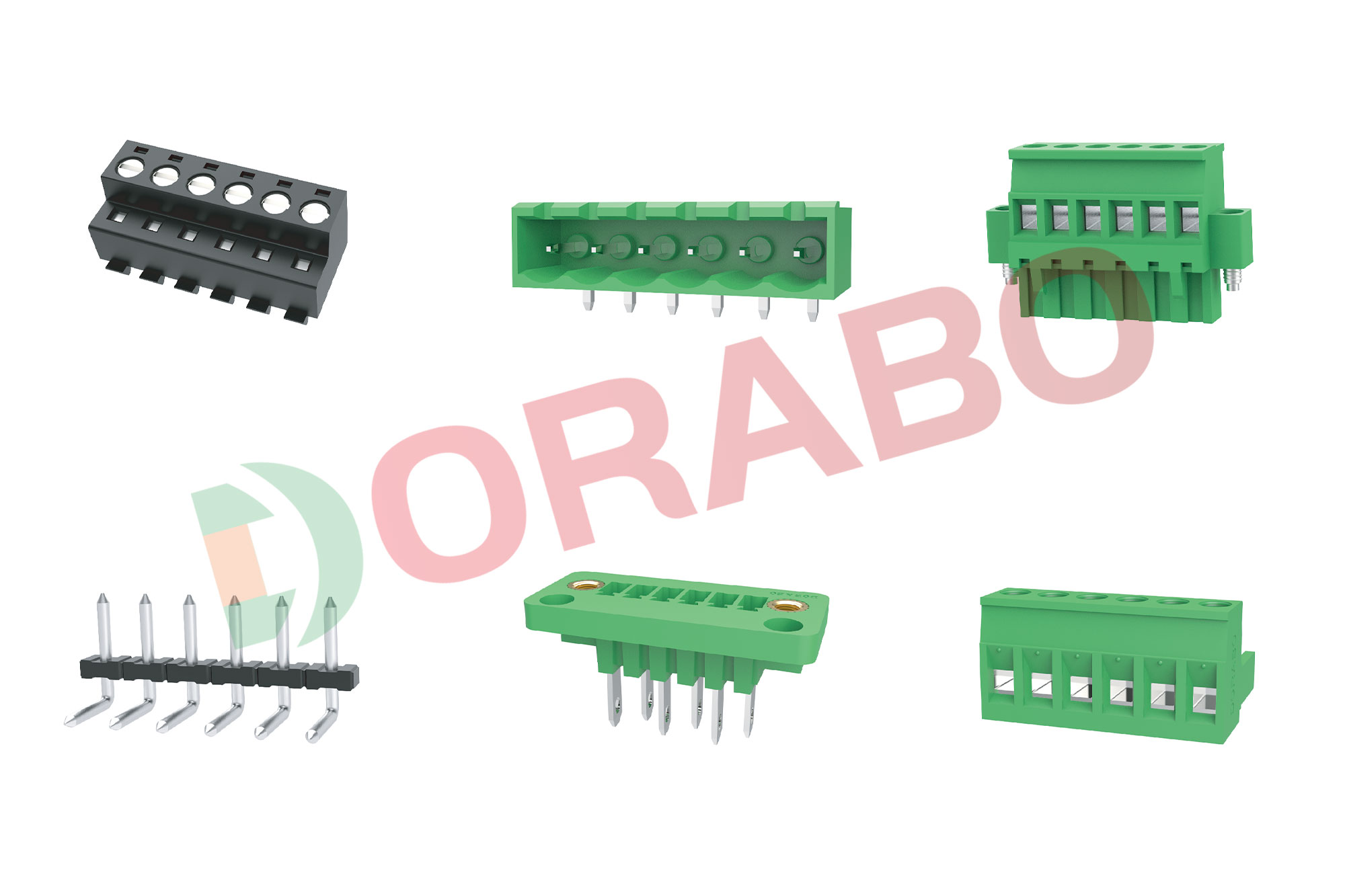

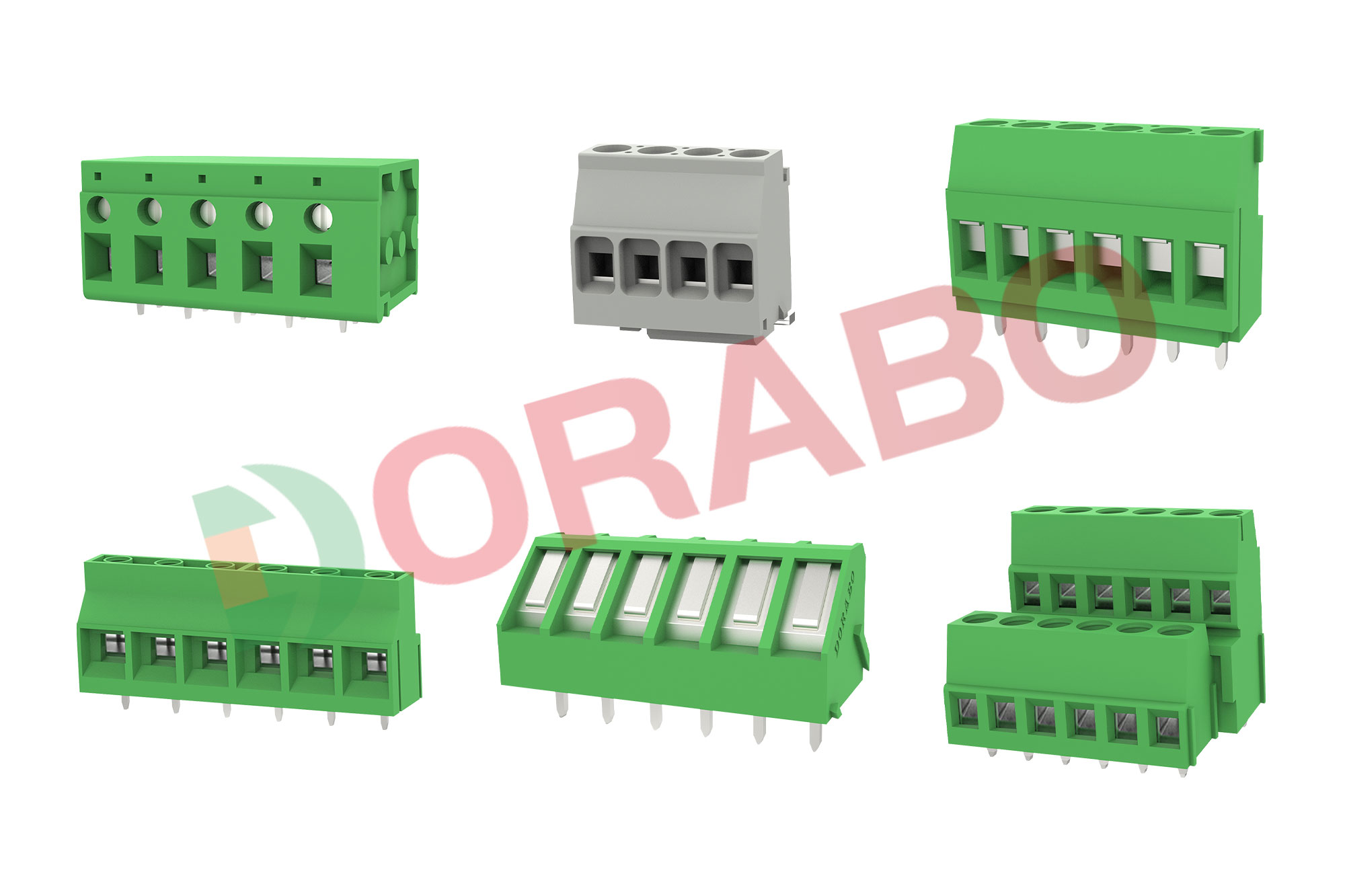

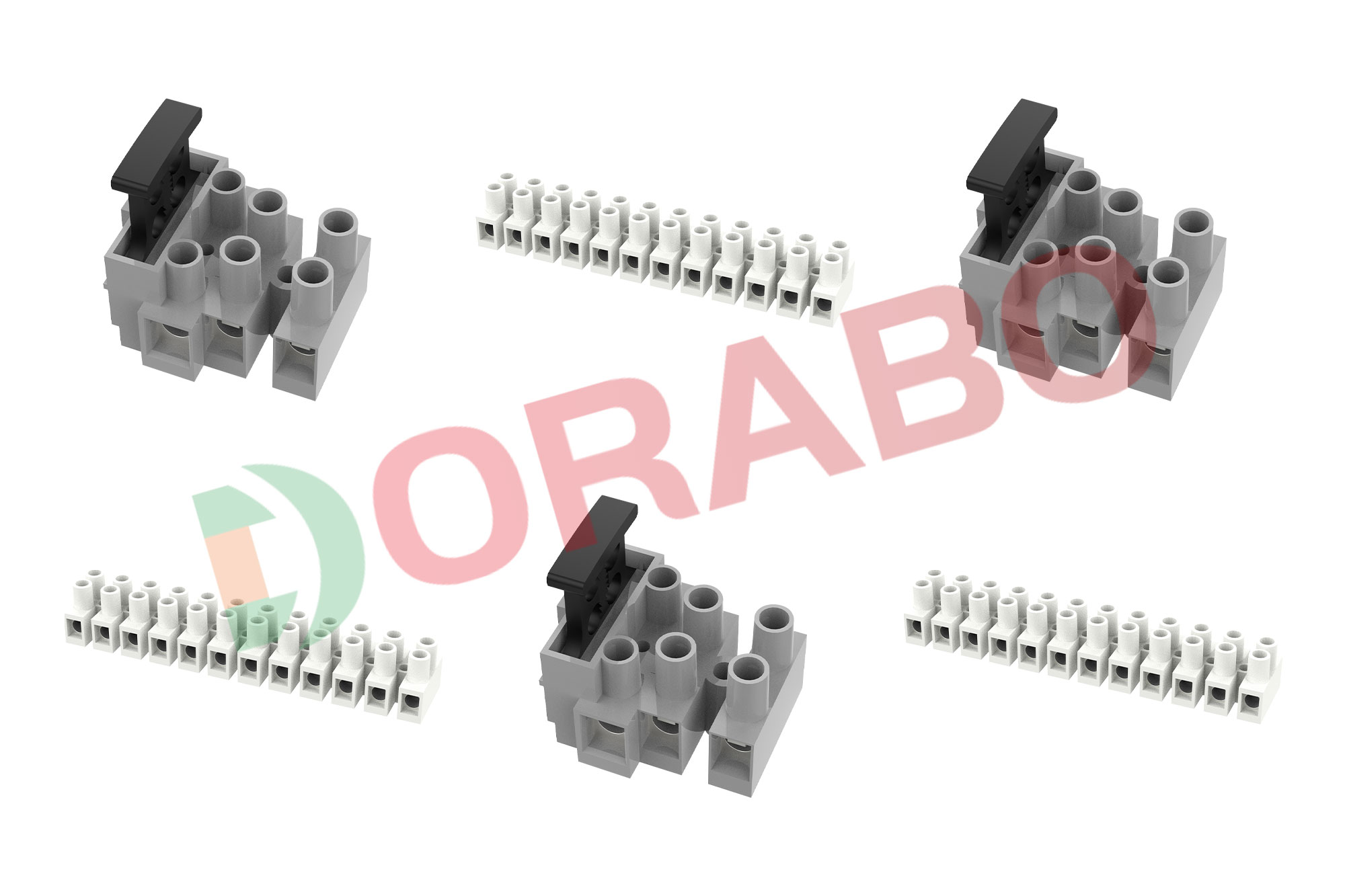

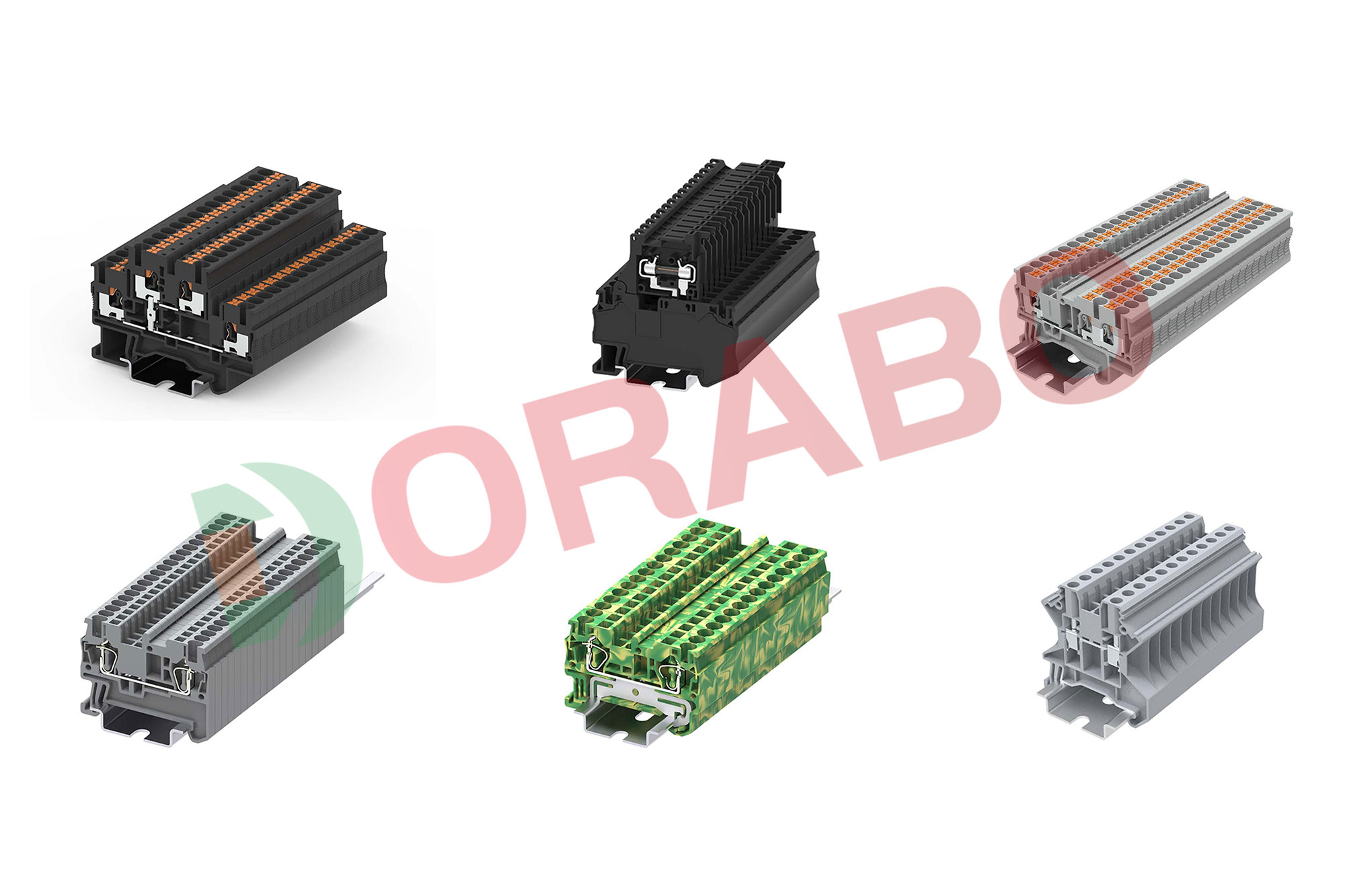

In China, the terminal block industry has been in the low-end market's sales range and occupies a relatively high market share. As users continue to demand terminal products, many manufacturers gradually enter the mid-range market. At the same time, the price war is also going on vigorously. In view of the strong labor resources, the country has always maintained a relatively high profit model. The terminal products required by the industry can be purchased in the market. The mainstream product series include rail-type terminal blocks, circuit board terminal blocks and so on.

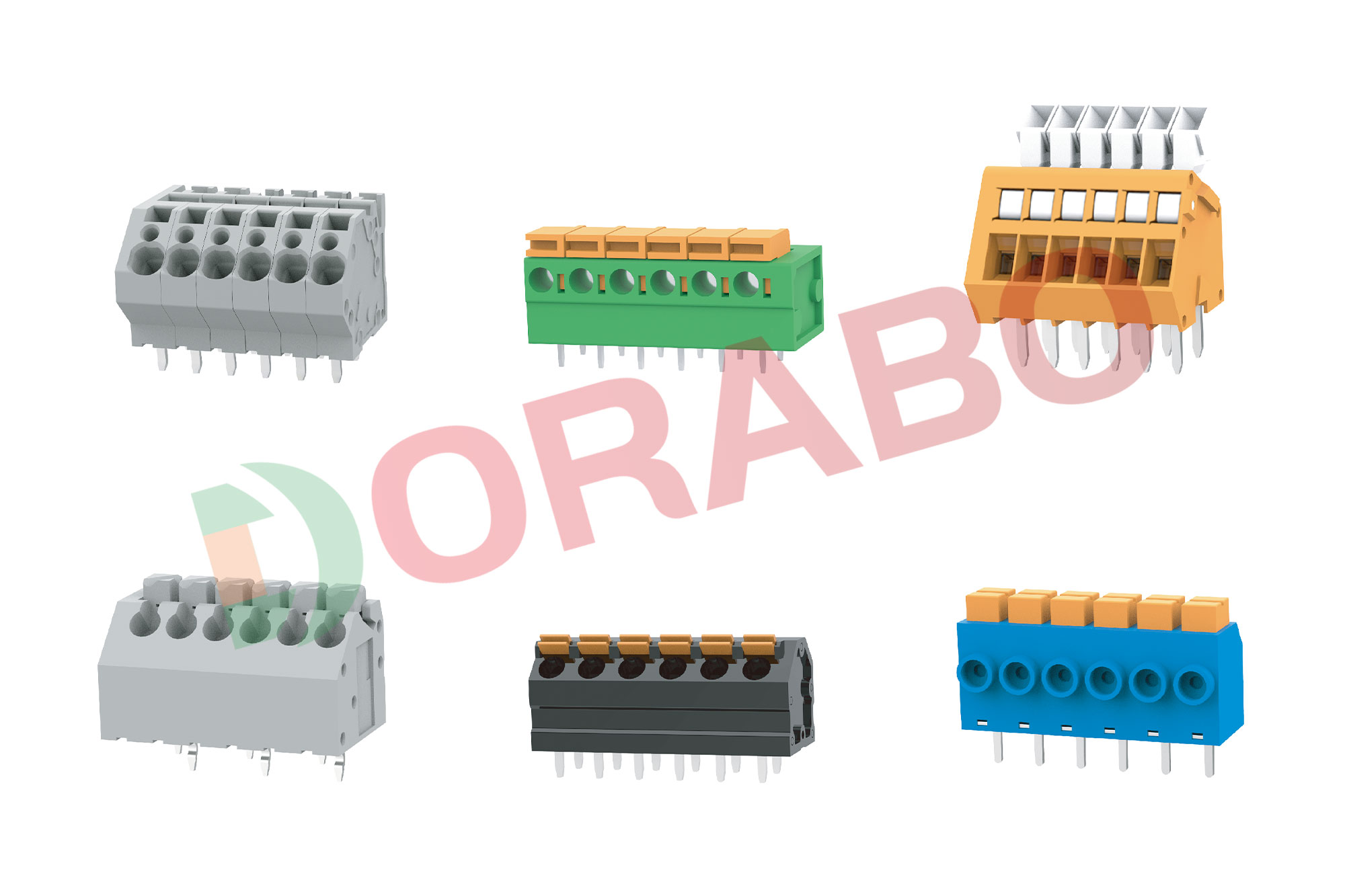

In recent years, with the development of electronic products toward high-tech, miniaturization, and high-performance trends, people's requirements for terminals have become higher and higher, and mold companies are facing higher and higher challenges and technical requirements. The requirements of the terminal manufacturing industry are mainly focused on:

1. The improvement of the requirements for the design level of the mold, because the design of different shapes of the terminal is different, how to make a reasonable design is very important, if the structure is unreasonable, the product will be unqualified;

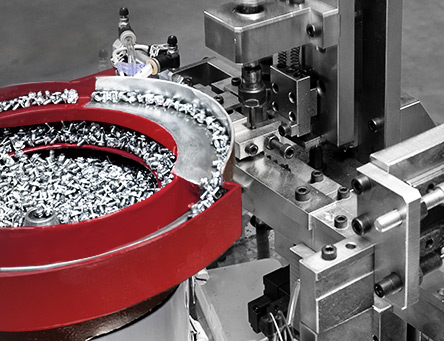

2. High precision Equipment, terminals require high precision processing equipment, foreign equipment accuracy can reach ±0.002mm, while the general domestic equipment can only reach ±0.01mm;

3. Excellent basic processing technology. A good connector mold requires a combination of design, equipment, and technology. At the same time, this requires high equipment compatibility and relatively high technical barriers. Guosheng adopts advanced CNC surface grinding, automatic optical curve grinding, slow-moving wire cutting, machining center and other equipment combinations for production.

Dorabo electronics experts predict that increasing user demand will force manufacturers to become more and more demanding on hardware molds, which requires higher requirements on the equipment, materials, and quality of connector molds. The punching speed of the mold used has reached 500 rpm-3000 rpm, this is undoubtedly a technical challenge for mold companies. To gain a place in the terminal industry, terminal mold companies have to step up the pace of industrial adjustment, increase scientific and technological innovation and capital investment, in order to produce high-performance terminal blocks that meet market demand and conform to the development of the times.

Contact us

Contact us Language

Language