What’s a component that forms the backbone of most motion or automation control systems but that oftentimes goes unacknowledged? We’re talking, of course, about the hard-working terminal block.

What exactly is a terminal block and what function does it serve in motion/automation systems? The most basic definition is that it provides an electrical connection point for two or more wires. Terminal blocks were originally referred to as screw terminals because a screw was used to secure wires to a conducting plate, making an electrical connection. In control systems, terminal blocks are used to connect panel-mounted equipment to power and field wiring.

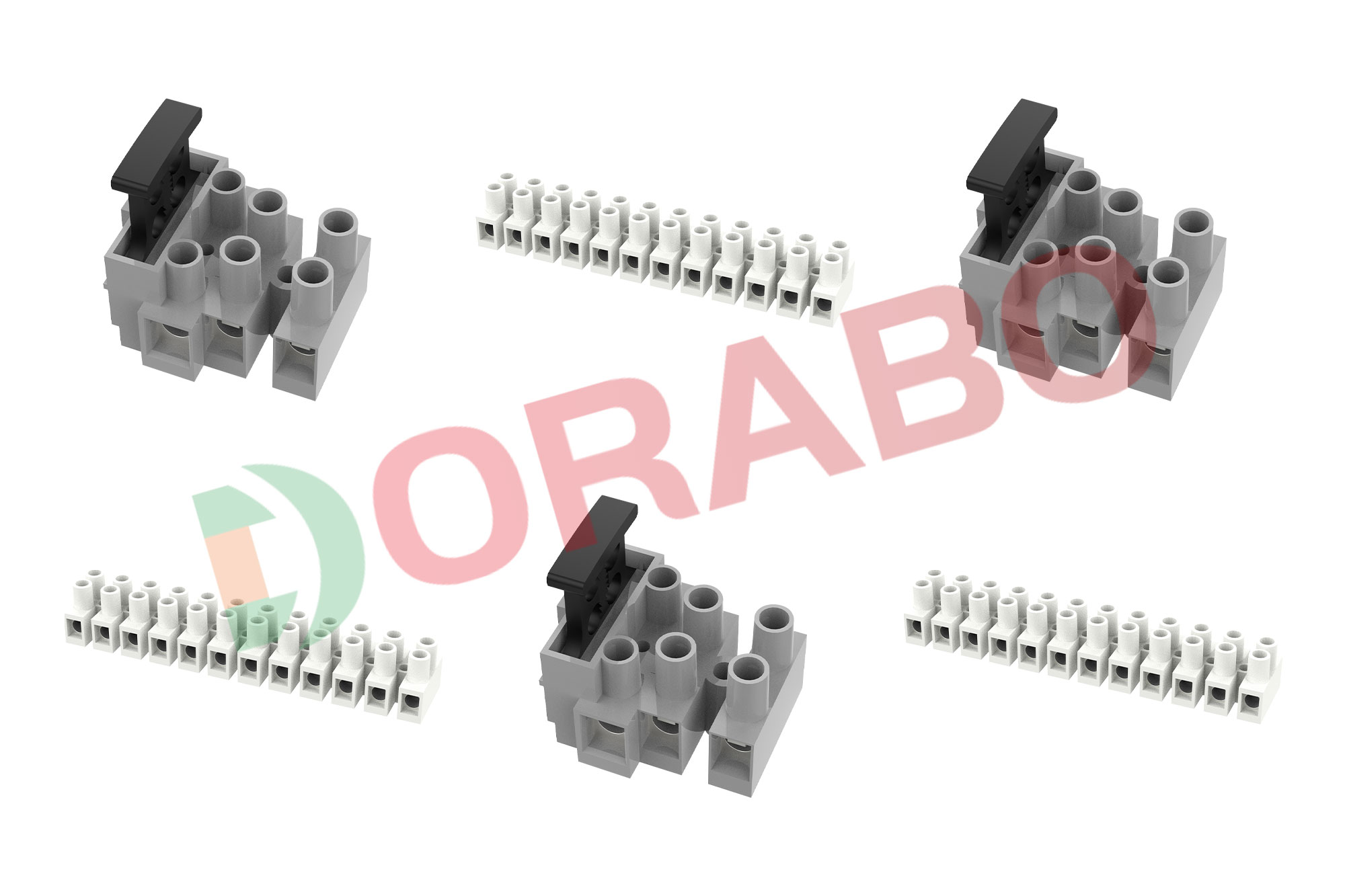

A typical control cabinet showing pluggable terminal blocks mounted to DIN rails with wire connections labeled for easy identification.

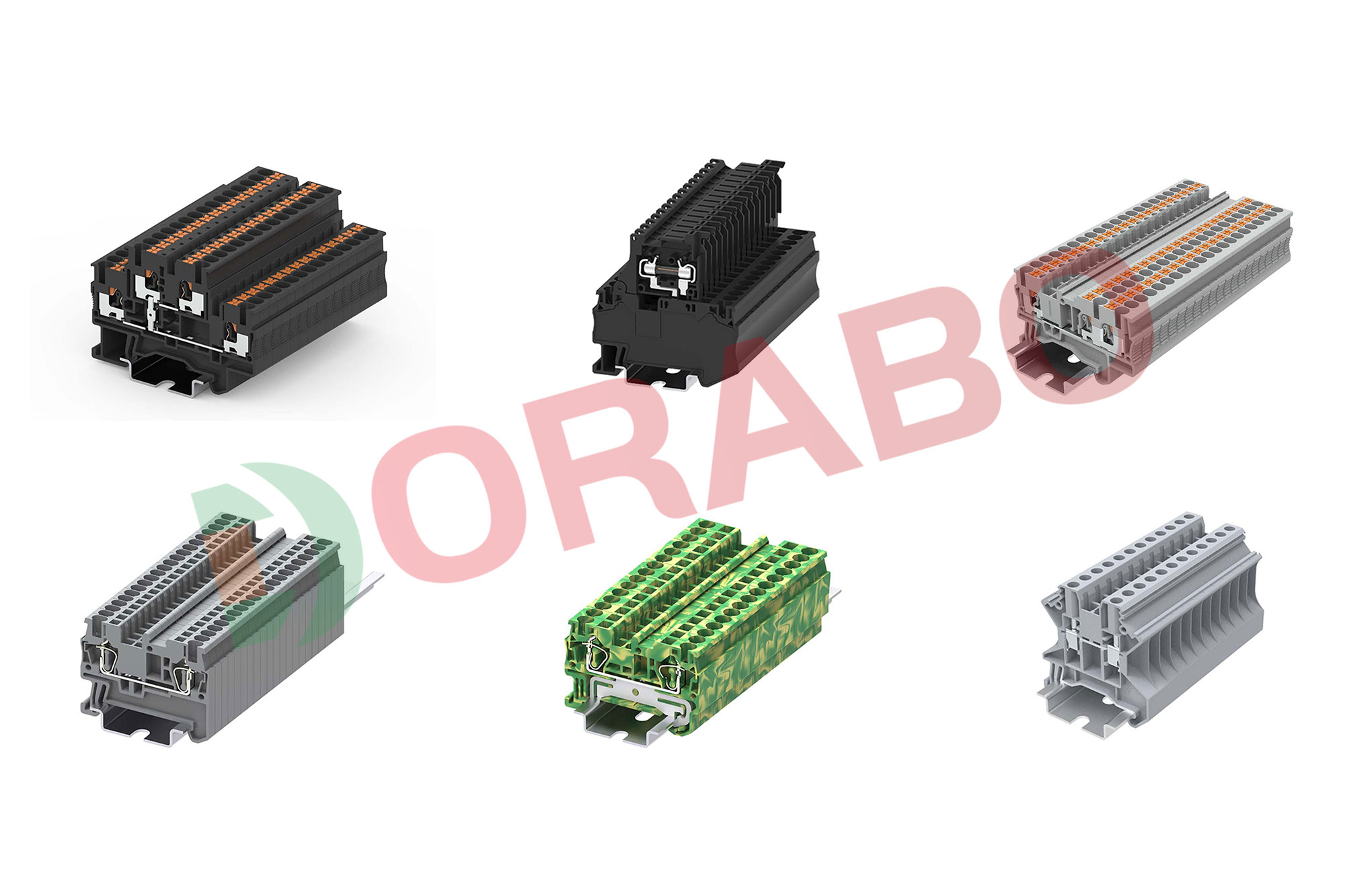

A typical automation system inside of an equipment rack may contain any number of components (such as controllers, PLCs, I/O modules, etc.) mounted on DIN rails and connected via terminal blocks.

Types of Electrical Terminal Blocks

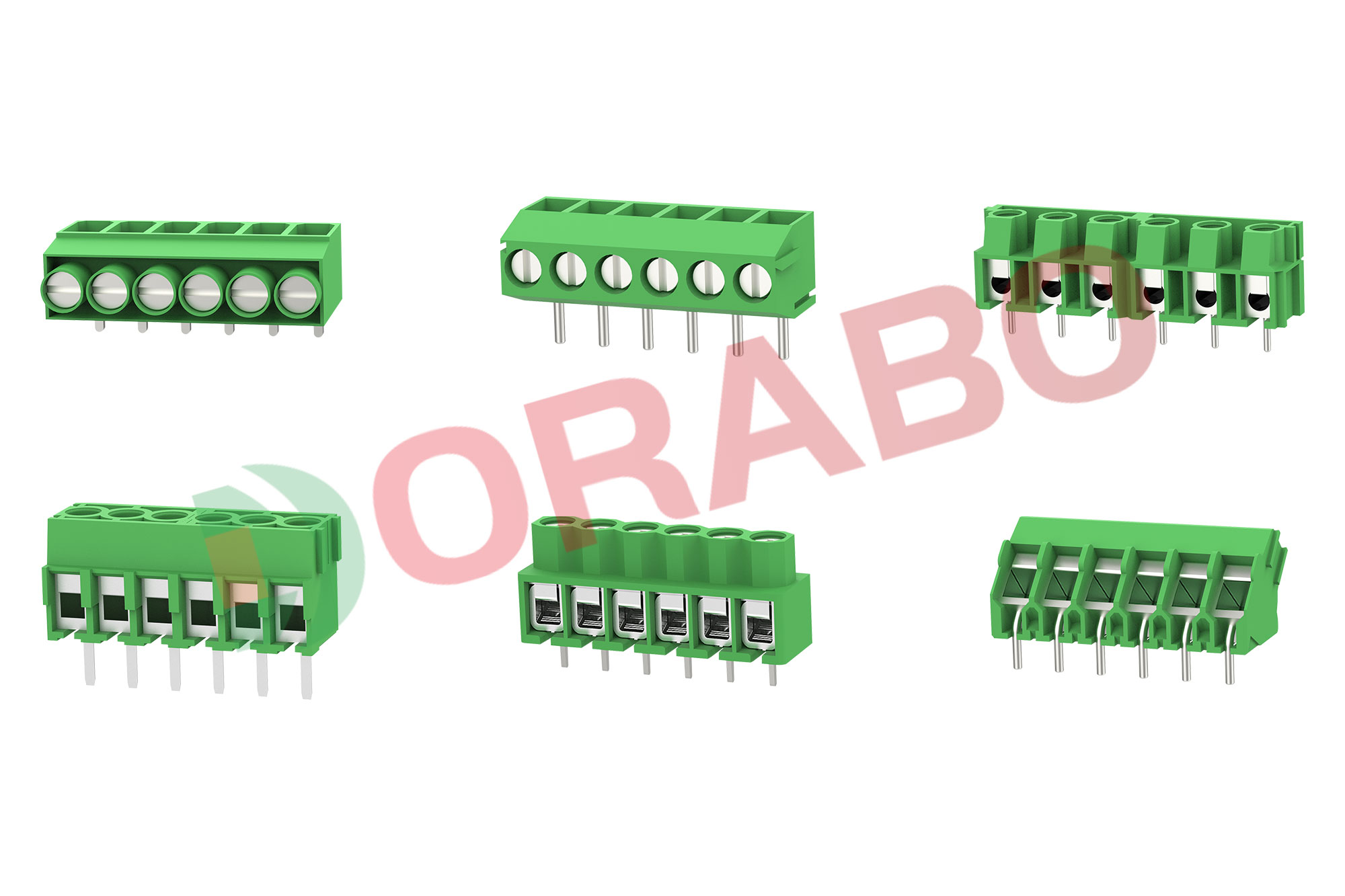

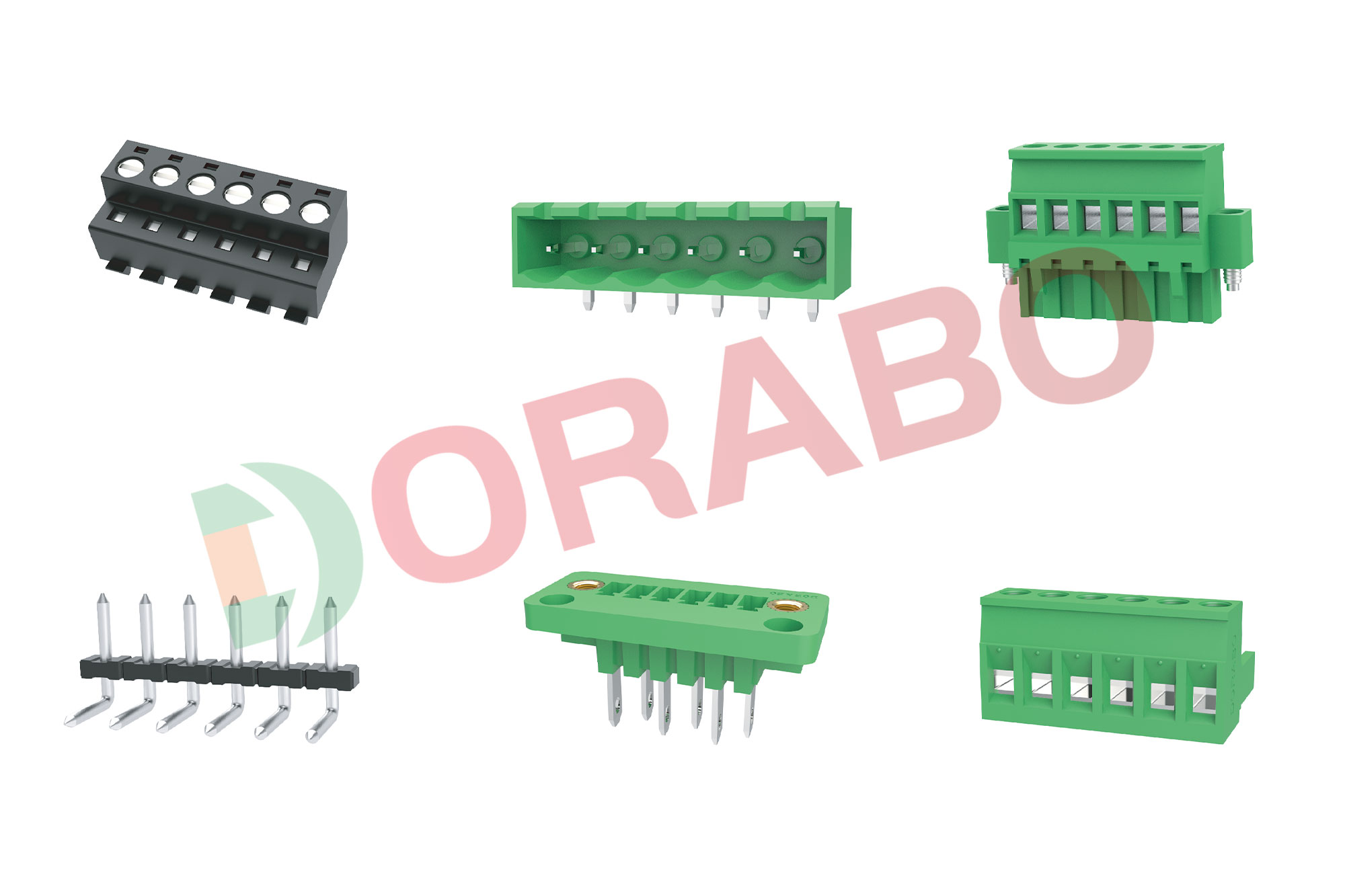

There are a large variety of terminal blocks for varying needs. General-purpose types are broadly used in many applications as simple termination points to make electrical connections. Other examples include terminal blocks for I/O, for power distribution, as well as for motor connections, both single-phase and three-phase motors for various industrial uses. Other common types include ground blocks designed specifically for making a connection to ground and fuse blocks where two wires make a connection to a fuse, providing circuit protection.

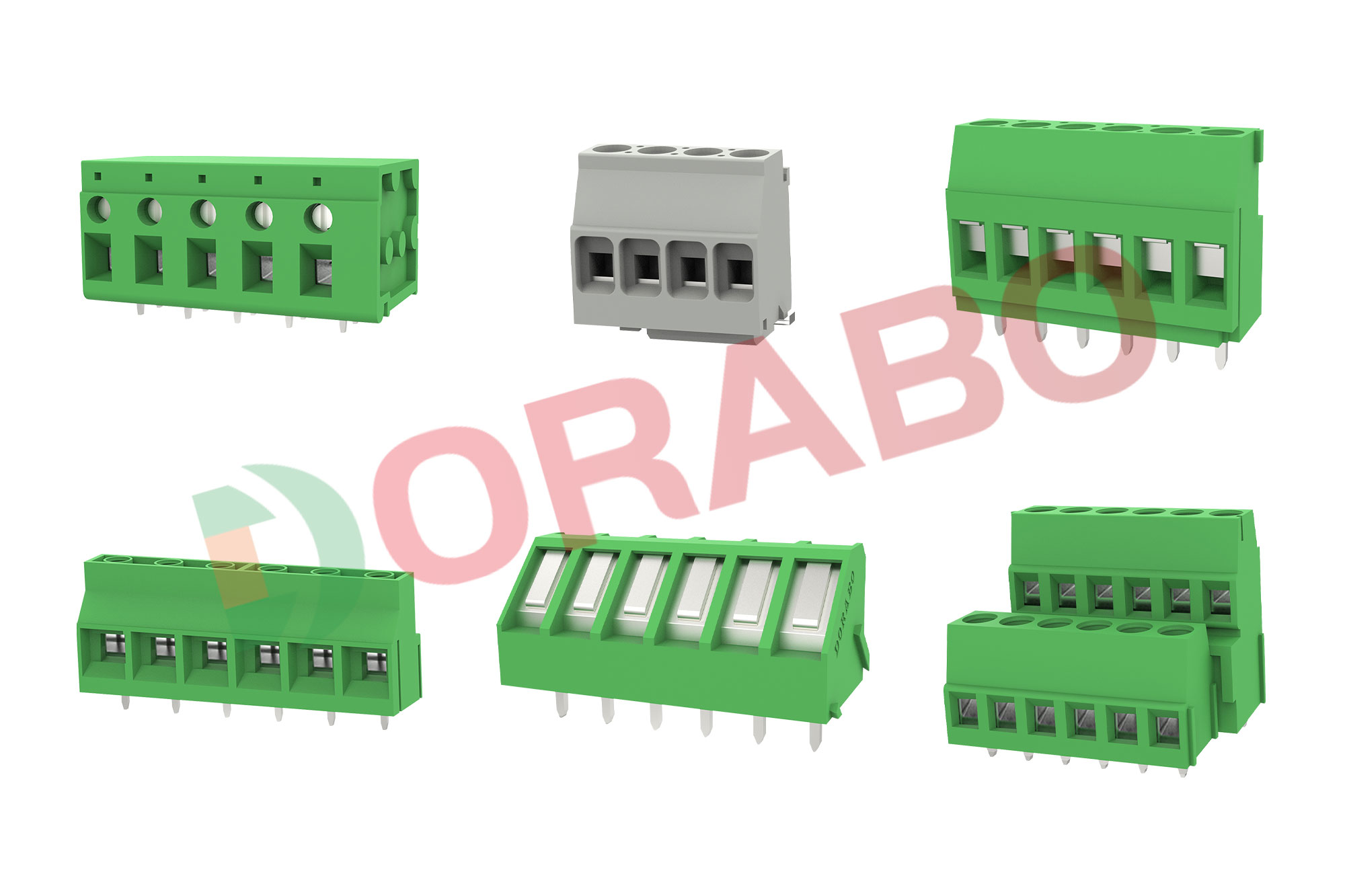

Wires are inserted on the side and make contact with a conducting bar and are secured in place with a screw tightened from the top.

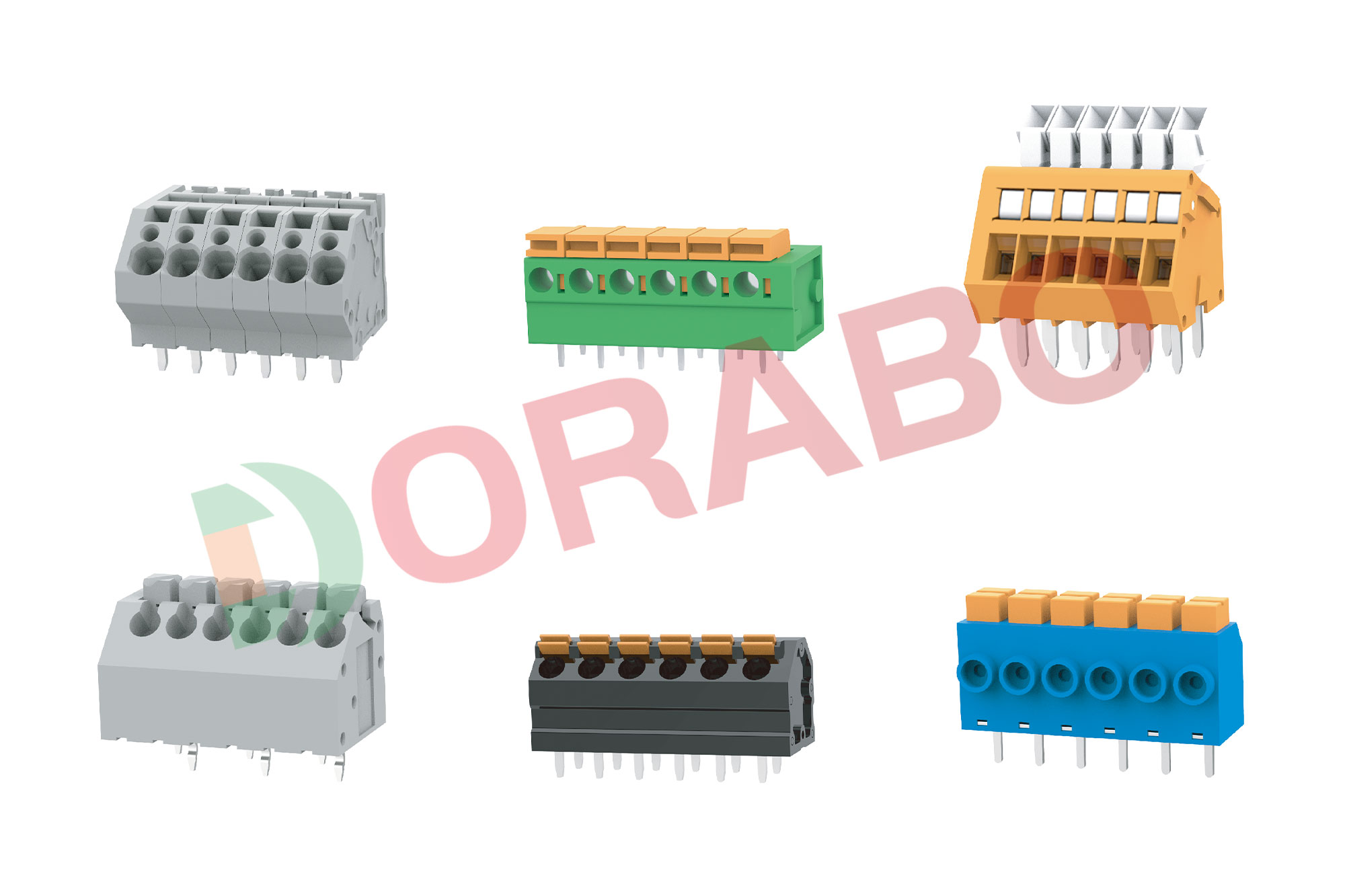

Another common way to classify terminal blocks is by the method of terminating the wire or making the connection. Terminal blocks are available with several different connection methods. The most common are screw-in types where the wire is pressed against a metallic conducting plate or bar and tightened down with a screw to secure it physically and make an electrical connection. Spring-loaded terminals use the force of a spring to maintain the connection of the wire to a conducting plate. There are also push-in terminal blocks where a wire attached to a ferrule is inserted into a hole in the block. Other types include insulation-displacement connectors (IDC) that don’t require the wire to be stripped before insertion into the terminal block.

An example of a DIN-rail mountable, multi-level, spring cage connection terminal block.

Other differentiating features may include the size of the terminal block, the number of possible connections, as well as voltage and current ratings. Typical examples can range from standard signal levels such as 1 to 5 V or 4-20 mA to power supply connections with high amperage current ratings and voltage ratings of hundreds of volts. Other important factors include the type of wire connections that can be terminated (i.e. stranded or solid wire) of different gages (AWG sizes), as well as the so-called levels, as in single (for a single wire-to-wire connection), double, or triple levels offering multiple connections on the same block.

Contact us

Contact us Language

Language