When designing a system that will use terminal blocks, you may know your overall system voltage and current requirements. While these are very important, there are other factors to consider in your design.

The voltage rating depends in part on the dielectric strength and spacing of the junction box enclosure. The maximum system voltage applied must be lower than the rated voltage. When choosing terminal blocks, you should also evaluate any voltage surges in the system.

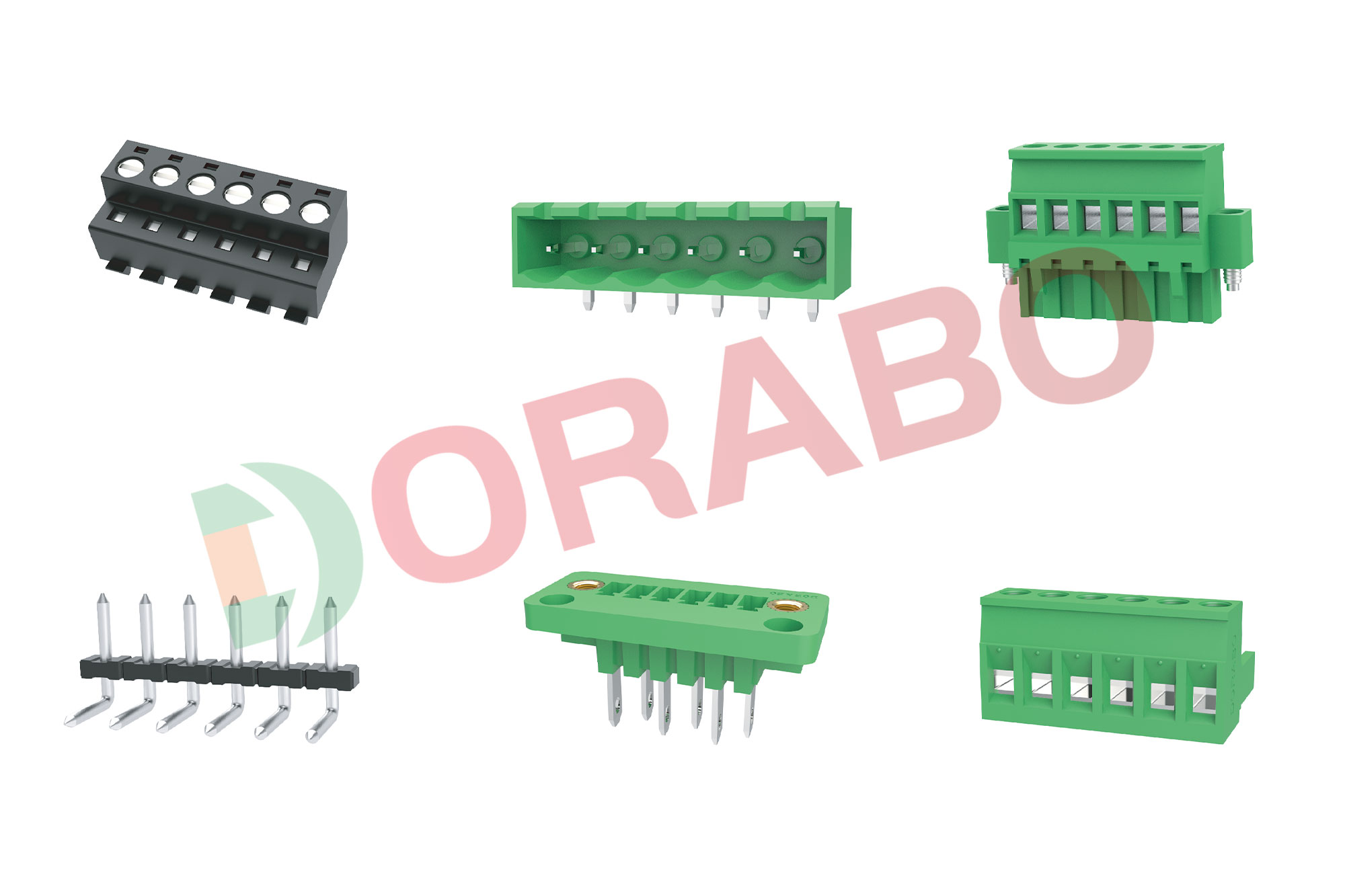

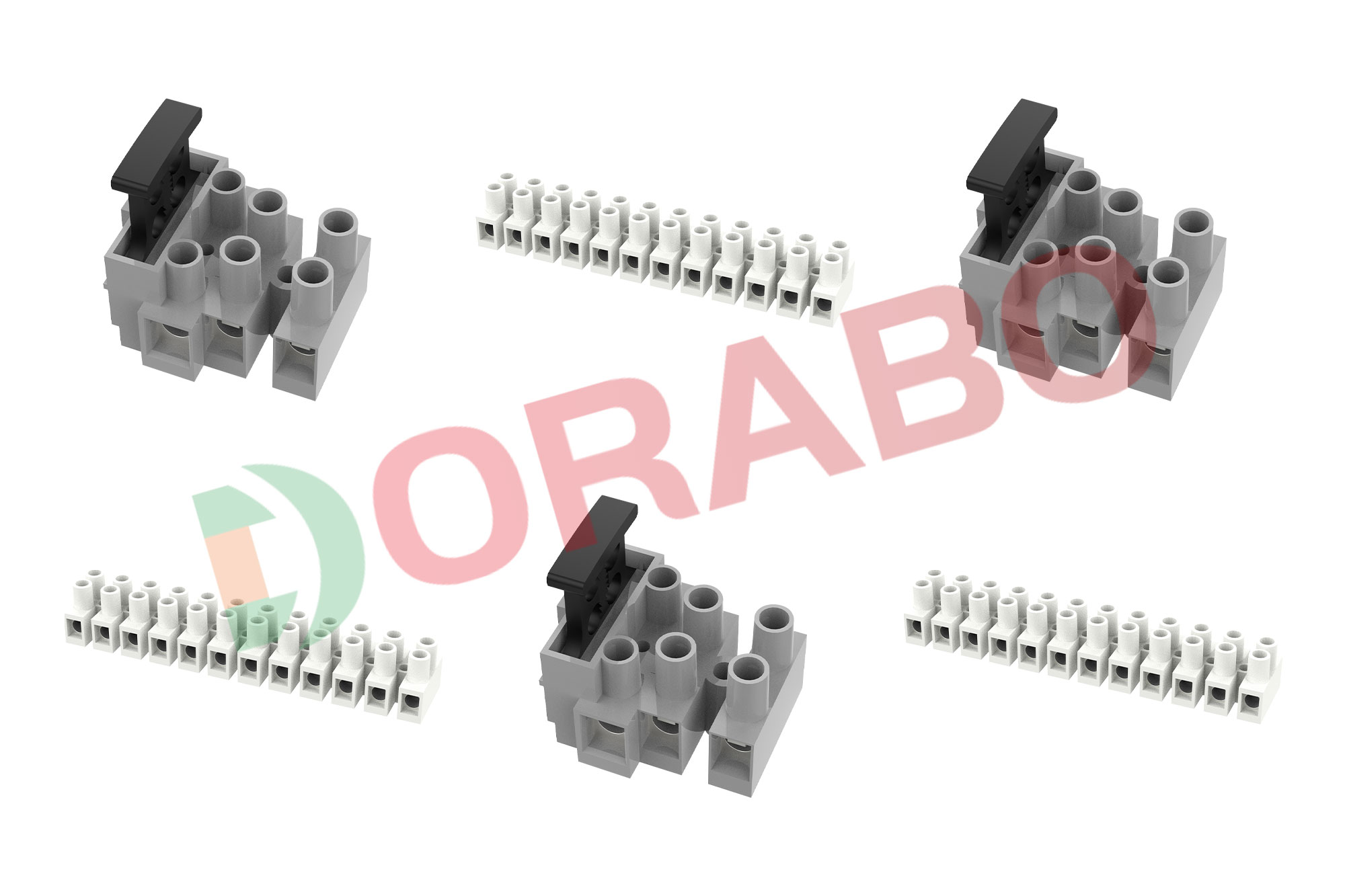

The number of individual circuits within a junction box is also called the number of poles. This can be as little as 1 pole to as many as 24 poles, depending on how many individual circuits are required in a particular application.

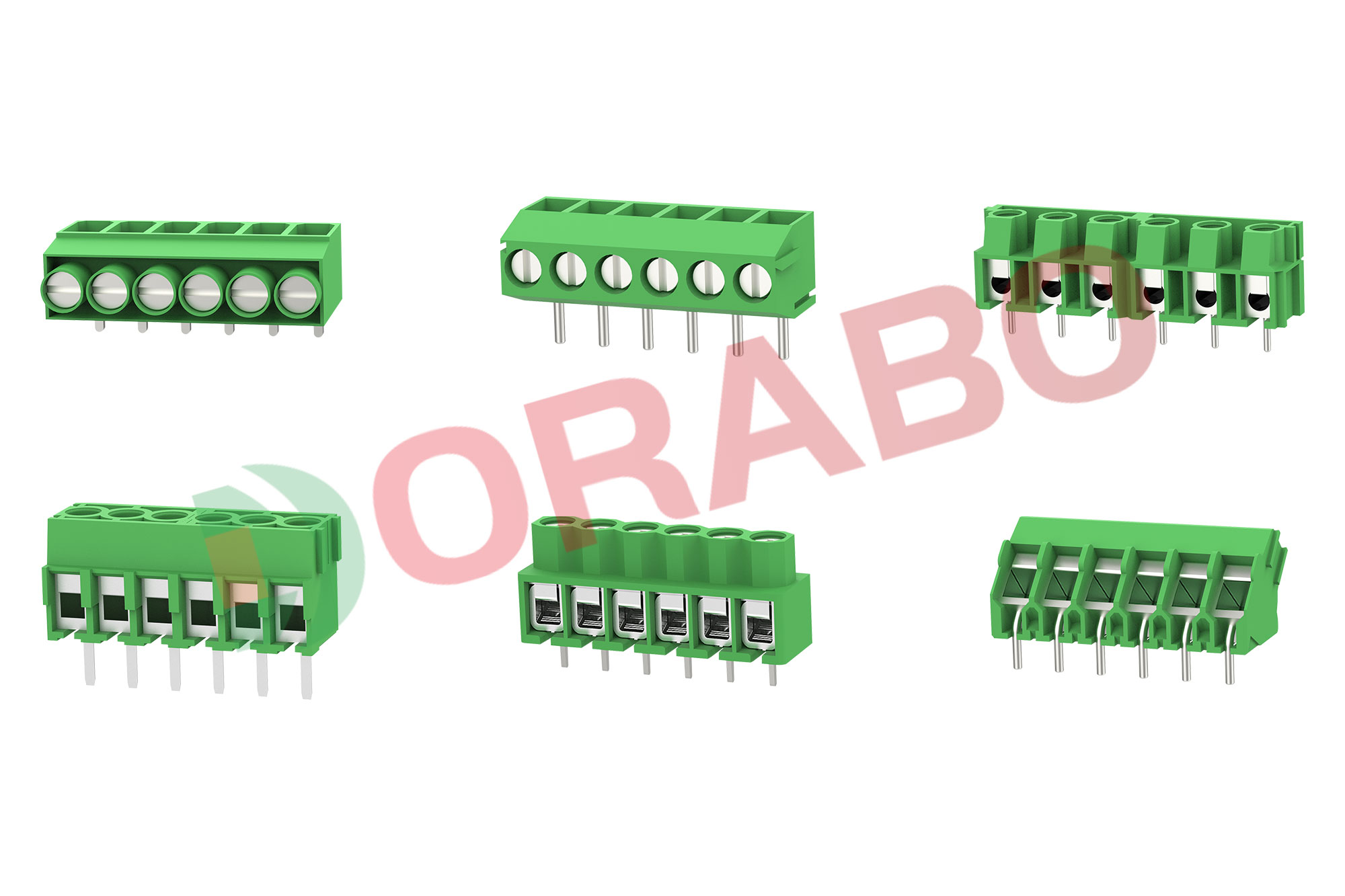

Terminal spacing is defined as the center-to-center distance from one pole to the next. Connector spacing is generally determined by the overall rating of the terminal block, which takes into account factors such as voltage/current, creepage and clearance. Common industry spacings will be but not limited to 2.54mm, 3.81mm, 5.0mm and 7.62mm.

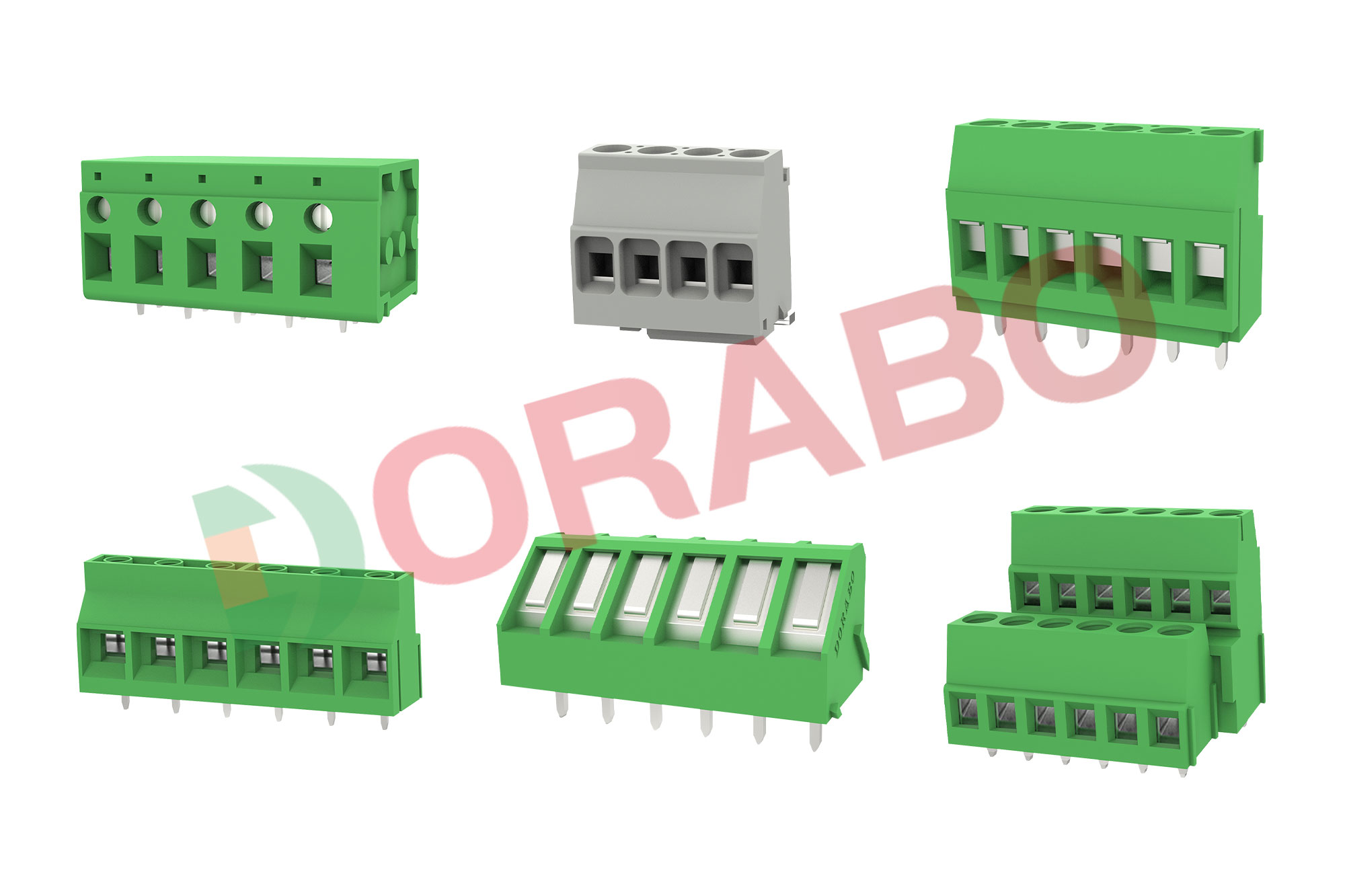

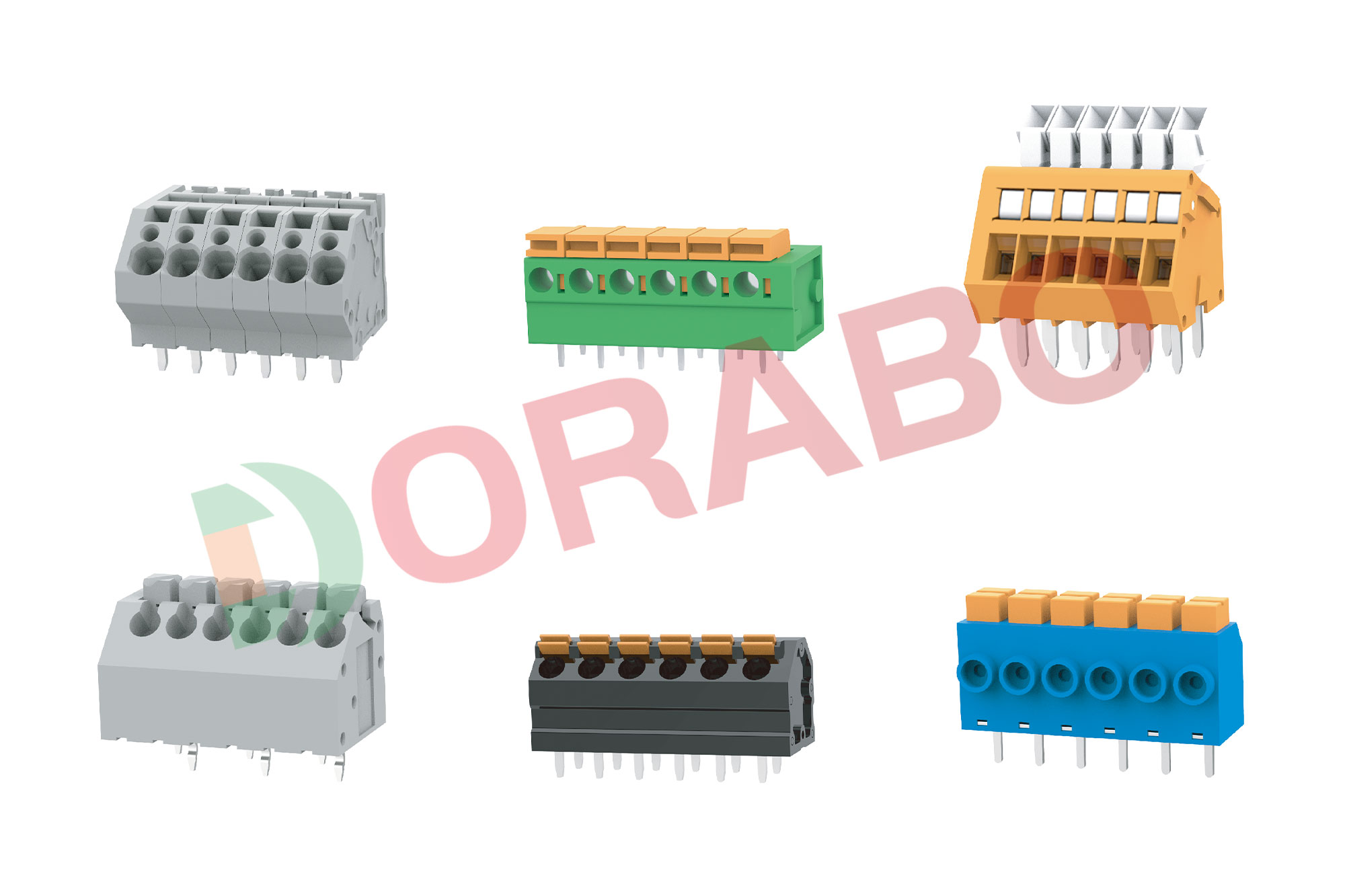

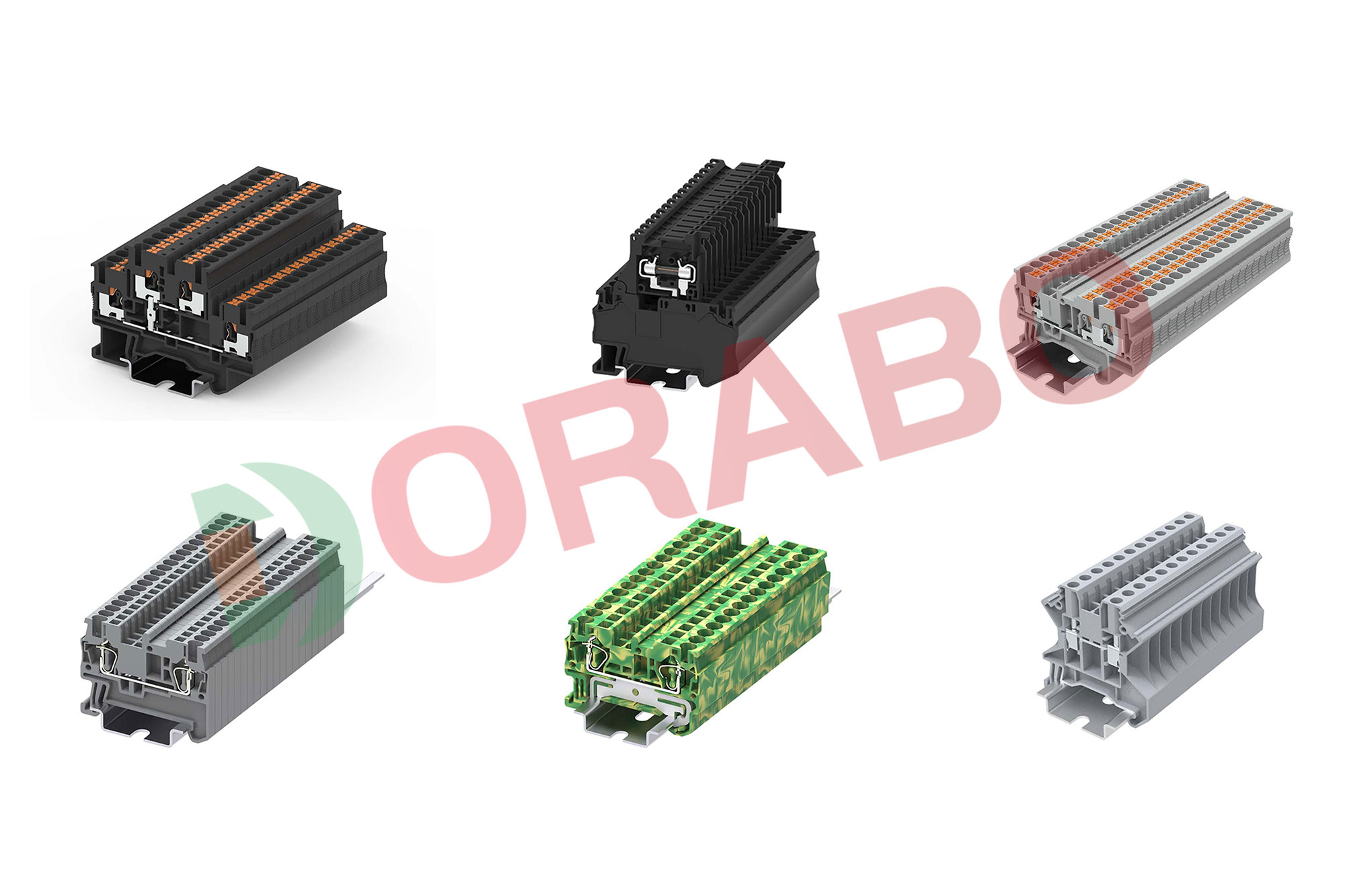

The minimum and maximum wire size that a junction box can accept is a function of the voltage/current rating. In addition to making sure that the wire being used will physically fit the terminal block, you should also consider the type of wire. Stranded or multi-conductor wire is usually used for screw terminals, and single wire is usually used for push-in terminals. In North America, wire sizes are specified in American Wire Gauge units.

In addition to system electrical factors, there are also mechanical limitations and constraints that need to be considered in terminal block design. The key feature to consider is any mechanical constraints on the design enclosure that may affect the overall footprint, orientation and accessibility of the connection.

Contact us

Contact us Language

Language