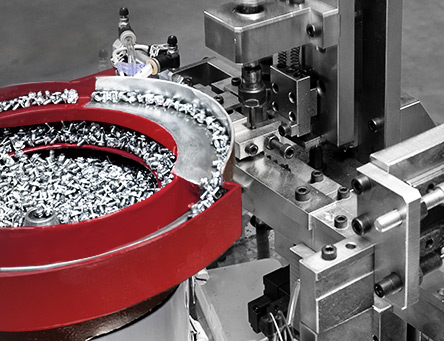

In manufacturing, early identification of process or product differences can be corrected early to reduce defects and improve efficiency. The Industrial Internet of Things (IIoT) enables a new method of positioning and reducing variability. ProcedureS that require variable components (such as temperature, pressure, and viscosity), or industries that require precise placement of components (such as automation), are benefiting from the ever-increasing number of sensors deployed and the insights derived from the data they generate.

For example:

- Commercial transportation companies are using vehicle flow sensor data to identify potential failures and perform preventive and predictive maintenance.

- Agriculture and mining companies are using sensor networks to coordinate the movement of field equipment, develop unmanned fleets, improve fleet maintenance, and improve safety.

- Automakers are using on-board diagnostic data to detect equipment failures, safety risks and defects.

- For oil and gas producers and refiners, downtime is a major issue, and the industry is using more and more sensors, networks, and analytics to generate predictive insights into equipment performance and predictive maintenance.

IIoT evolution

As shown above, IIoT is rapidly evolving from concept to reality. It is driving the growth of ultra-low power consumption (ULP) wireless technology, which will ensure ultra-efficient data communication for sensor arrays and other devices in the Internet. The ULP wireless protocol will have several competitor options, but it is unclear what the leading technology will be.

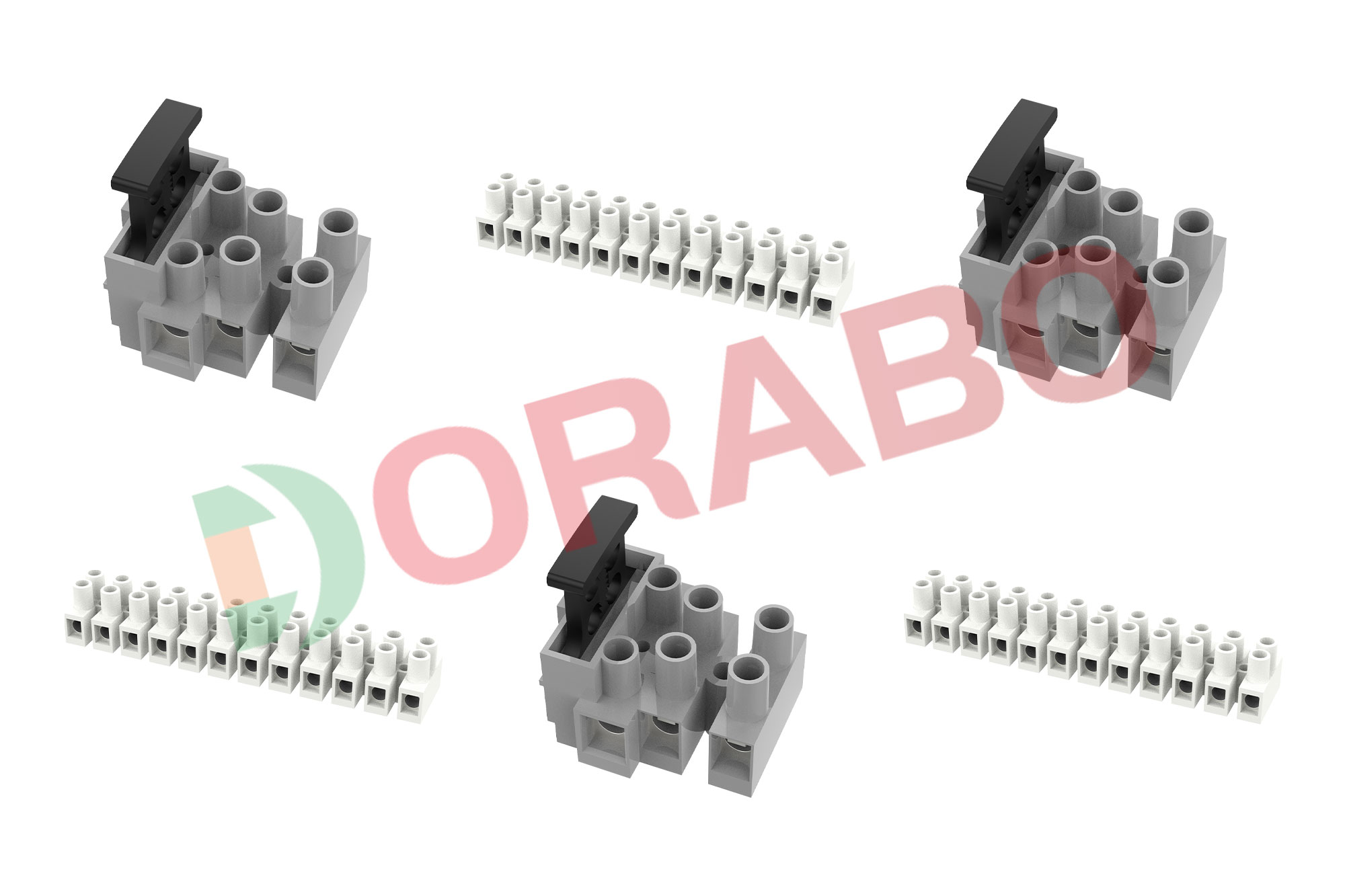

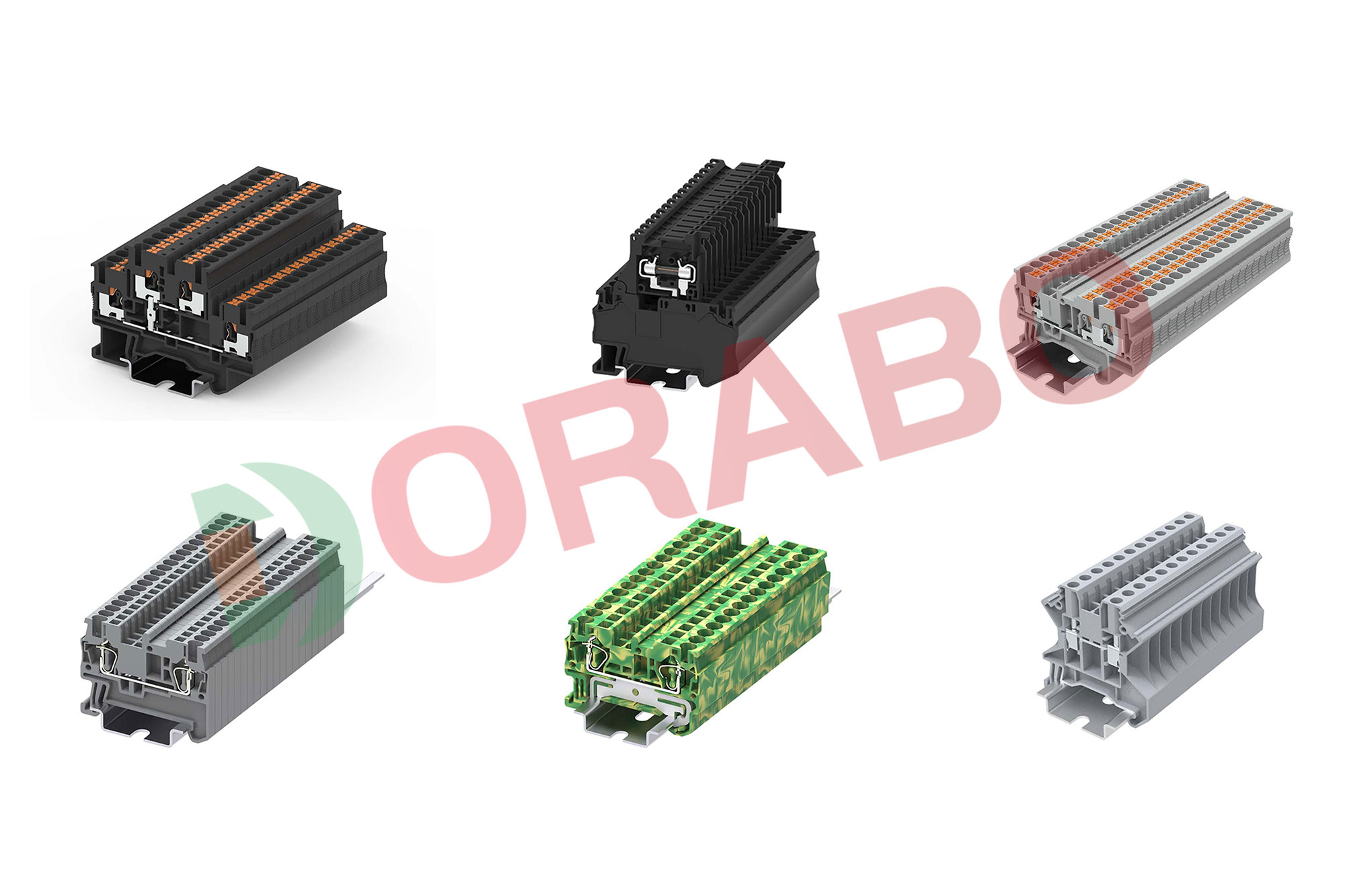

The wireless platforms that support IIoT are based on standard and custom RF coaxial connectors, cable assemblies and antennas. Moreover, IIoT needs unique solutions, such as communication technologies including cellular, UMTS、Wi-Fi、bluetooth, GPS, etc.

Although many of the technologies that provide power for IIoT are not yet fully mature, sensors have been used for many years and have reached a certain level of maturity. The above two types of sensors, temperature and pressure sensors, are now used in a large number of devices. The accelerometer is now the main function of mobile devices, allowing the display to "flip" and change with the orientation of the screen. In addition, the magnetometer provides an electronic compass function, and the gyroscope stabilizes movement-such as a camera lens

Multifunctional Fusion Sensor

Many of these independent functions are now incorporated into multifunctional or "fusion" sensors, and we can see that this trend of space and cost saving is accelerating. These convergence centers will be used for the entire Internet of Things (IoT) and IIoT at the same time.

In addition, sensors will get help from new industrial protocols such as IO-Link. These agreements will make sensors become smarter, provide more sensing functions, and enable internal diagnosis and maintenance information sharing, while maintaining low interconnection costs. The infrastructure installed on the factory floor or in other industrial applications is transitioning from proprietary and serial Fieldbus to newer Ethernet-based networks, such as PROFINET or Ethernet/IP, to accommodate the higher data volume required by these new features. The infrastructure itself is migrating from passive media to active control and monitoring in order to decentralize data management and increase data availability.

Technology fusion

Although these agreements are crucial, it is important to remember that IIoT is a vision realized by technological convergence. A key aspect of the convergence process is the development of a new generation of sensor chips, such as temperature and pressure sensors. The second factor is the advent of IPv6 addresses, which enable an almost unlimited number of people and devices to communicate over the Internet. Third, we have seen the development of several competing protocols for ultra-low power (ULP) wireless connections, which allows sensor-based networks to consume only a small amount of power.

The above-mentioned technologies have developed rapidly in IIoT and other areas of the Internet of Things, which can enable the development of almost endless new applications and improved efficiency. They will be the drivers of major innovation opportunities. However, IIoT deployment still faces doubts about traditional thinking and concerns about security issues. These problems must be resolved before the industrial equipment and machines in the factory are open to the Internet and fully benefit from the potential of these new technologies.

Powering the Industrial Internet of Things-released on the connector supplier on November 11, 2016

Contact us

Contact us Language

Language